inquill | custom pen plotter

designing and building a homemade cnc pen plotter that plots g-code extracted from vector drawings (using inkscape & gcodetools) and brings ideas from your screen to actual paper [aka homework writing magic tool *winks* /j]

since i missed out on #blot big time, i'm hoping to build something that:

⤷ is low-cost and fully 3d-printable + cute !!!

⤷ is mostly beginner-friendly (for use, not building)

⤷ can be assembled and run without soldering

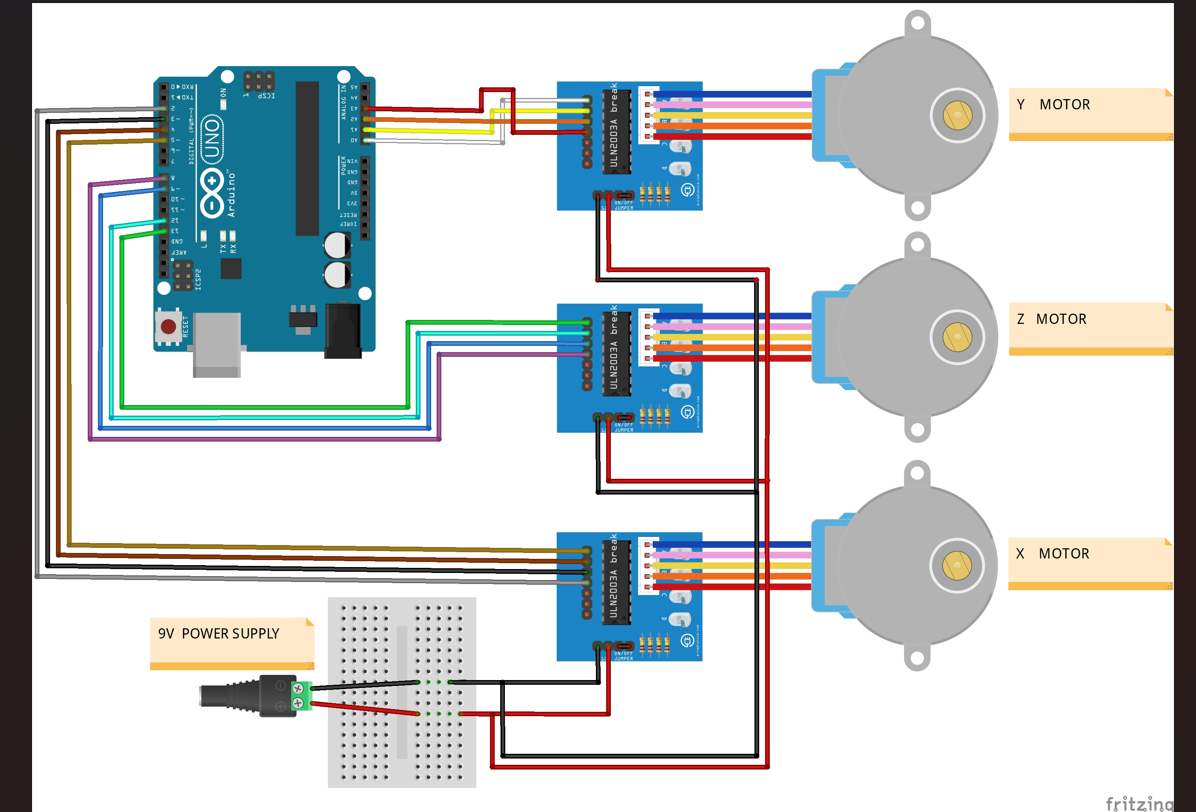

⤷ uses arduino uno + cnc shield + a4988 drivers

⤷ actually works (fingers crossed + chants prayer)

the pen plotter would consist of the following features:

⤷ arms that swing into a compact folded state for easy storage

⤷ pen lift functionality

[ps. relax, i am not submitting this for highway since i want to restart from scratch and make an entirely different full scale cnc router that goes beyond just the pen plotter functionalities]

Followers

cskartikey

Check their project out: The Journey

Neon

Check their projects out: Hacker news checker, Market , Artophage, Slack - Zeon

Ship Your Project

HOLD UP

By shipping your project, you're marking it as complete and it'll enter matchmaking. However, you will NOT be able to edit it anymore.

Timeline

edited xrail a lil

[this was supposed to be ~1.5hrs i forgot to turn the timer off HELP] verified stepper and servo wire lengths reach moving parts without binding + added like 0.2mm tolerances to moving parts but im not very sure ??? gonna work on combining the subassemblies when fusion stops crashing again and again and again idk what it has against me

added strain relief notch for power cable and usb + verified stepper and servo wire lengths reach moving parts wo binding :3 aah its kinda coming together !!!

designed mounts for arduino + cnc shield under the base plate. created snap-fit wiring clips, wire guide tunnels along the arm.

checked alignment of belts, movement clearances, and servo reach, added bolt holes, countersinks, and adding nut capture slots.

sketched pen lift mechanism using sg90 servo & pivoted pen platform + drafted pen mount w adjustable screw clamp to hold different pens. started combining x, y and z subassemblies

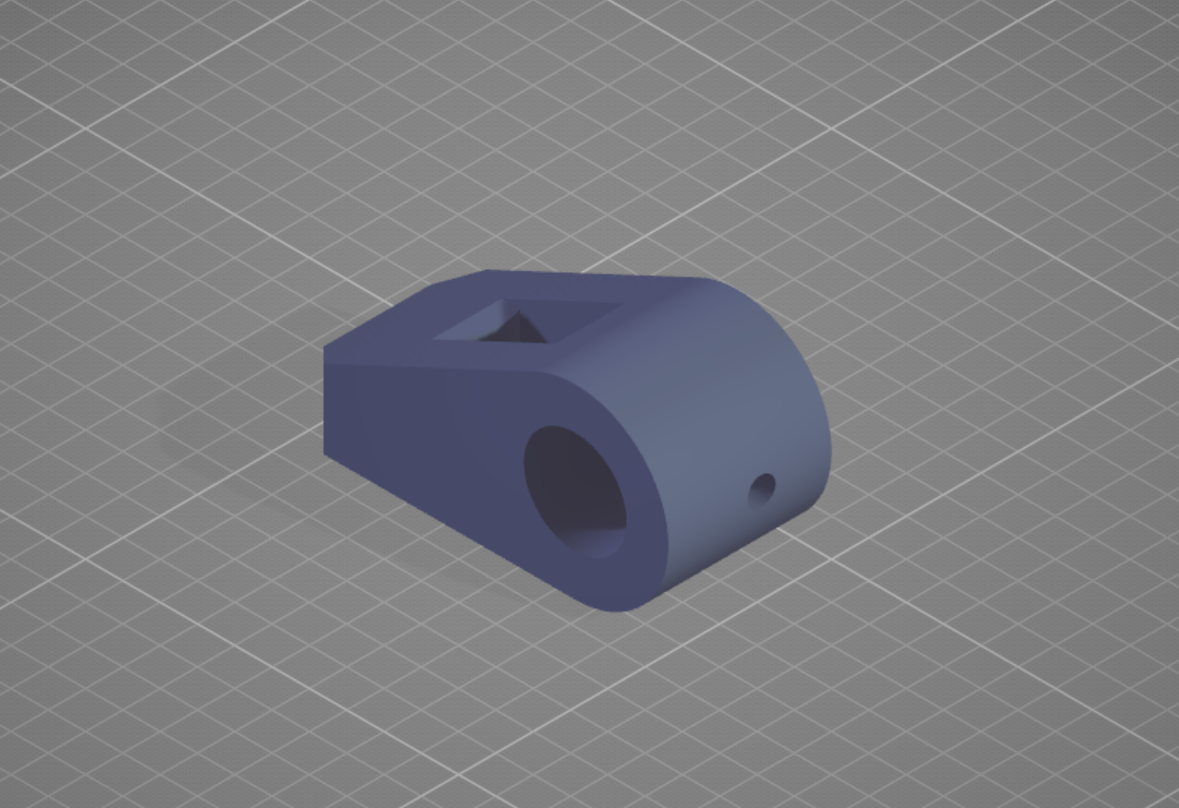

created y-axis carriage to ride on the x-rails using v-slot-style contact w printed bushings + added linear grooves & side flanges to the rail

designed idler holders with embedded m3 nut traps and tension slots + motor pulley adapter for gt2 belts. simulated belt path across foldable arms using fusion joints.

modeled the x-axis rail system (parallel beams joined w belt clamps) & laid base for designing idler holders with embedded m3 nut traps and tension slots

working on the cad !!!! designed the base plate (200x200 mm) with mount holes for stepper motors and hinge arms. tried to sketch foldable x-axis arms that could be made with bolt-based pivots.

worked on the circuit diagram for my intended project (did a bunch of research also)